Spike our Gold, Black-laced, bearded and crested Polish Frizzle, to give him his complete title, faces up to his metal, fire-breathing friend. Whereas, (below) the rest of the flock see this new member as an additional source of heat to the sun. Not sure about Rooster Rocket as a source of vitamin D₃ though - tea and coffee, yes.

Improving our Coffee Making

8 years ago I made a rocket stove for using whilst working in the garden and also to avoid having to light our wood cooker just to make a coffee. The burn tube and chimney were fabricated from some scrap mild steel pipe 4" in (102mm) diameter and this was installed in an empty steel cooking oil drum donated by a caterer at an Autumn fair. I insulated the pipe by packing wood ash around it and made a burn shelf from some scrap mild steel sheet on which the fuel would sit.

8 years ago I made a rocket stove for using whilst working in the garden and also to avoid having to light our wood cooker just to make a coffee. The burn tube and chimney were fabricated from some scrap mild steel pipe 4" in (102mm) diameter and this was installed in an empty steel cooking oil drum donated by a caterer at an Autumn fair. I insulated the pipe by packing wood ash around it and made a burn shelf from some scrap mild steel sheet on which the fuel would sit.

The results were encouraging in that water could be brought to the boil in around 10 minutes. The fire had to be continuously monitored as the fuel needed to be fed into the burn area. The combustion was smoke free when properly tended and the consumption of twigs was low.

L to J

Spurred on by the results from the stove, this year I decided to improve the design by changing the pipe configuration to a 'J' - tube rocket. The advantage of this format was that the fuel, being held in the vertical (the short leg of the 'J'), would gravity feed into the combustion region of the burn tube, that region would preheat the incoming fuel prior to ignition thus making a fast, clean burn without the need of manual feeding. I should stress that the amount of human management of the combustion in the original horizontal feed only arose because of the small diameter of the fuel I was burning. Larger rocket stoves burning bigger branches require much less frequent attention.

The new stove comprised 3 lengths of pipe; feed tube, burn chamber and flue/chimney. Reading around I found that an ideal ratio for the lengths would be 1:2:4 the latter being the flue length which could be longer to generate more draft. The pipe internal diameter would be the principal unit in the ratio meaning that the three pipe lengths for feed, combustion and flue tubes would be: 4", 8" and 16" (102mm, 204mm, 408mm) respectively.

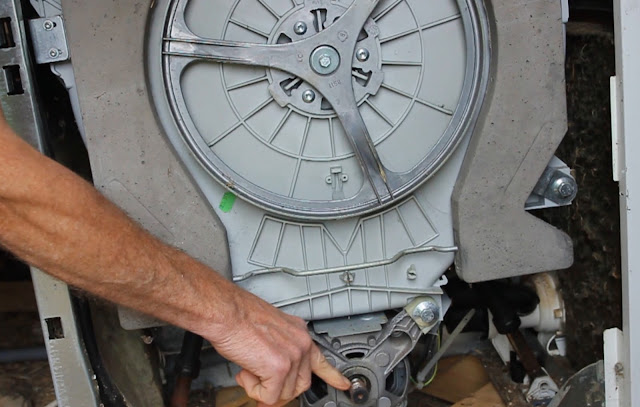

Obviously, I decided to re-use the original welded pipe to give me the first two zones of the new stove so the only additional pipe was that for the flue. The pipes were cut to a 45° angle at the joining faces to produce the right-angle mitred joint. The proximity of the two vertical sections of the arrangement did give me some concern as I thought it could give a problem with the accessibility for welding, ultimately this proved not to be the case but I feel it is worthy of mention. I also decided to cut the open end of the feed tube to 45°.

Once welded, I was able to check weld integrity by supporting the J vertically and filling the pipes to above the welds with water.

Legs for the stove were cut from mild steel bar removed from some old windows. I decided to use three legs as this configuration is the most stable when on an uneven surface. Two legs were welded at the flue side of the stove at an angle of 45° and I used the mitred weld as the guide for correctly positioning the first leg. The third leg was welded vertically down the feed tube.

I wanted all three legs to be cranked out from the stove body so as to have a more stable geometry. I laid the assembly on its side and slid a steel tube along the first of the flue-legs. By keeping my foot firmly on the leg that was touching the ground, I could bend the leg out from the stove body.

For the second leg on that end of the stove I turned the stove over, supporting the stove flue on a piece of steel I use as an anvil. Again using the steel pipe, I could bend it out to the same angle.

The third leg had been cut oversize and once bent, I stood the stove up on its three legs to determine the correct length and cut off the surplus.

Finally I needed to attach a pot support above the open end of the flue. The distance of the base of the kettle/saucepan from the open end of the flue had to be sufficient so as not to impede the flow of the out-flowing gases of combustion. I calculated the height by determining the area of the stove flue and converting this to the wall surface area of a cylinder of the same diameter i.e. Area=πr²=2πrh cancelling h=r/2 which equated to 1" (25mm).

Using the same bar as for the legs, I bent 3 short lengths to a right-angle and welded them, equally spaced at the flue top and to a height of 1" above the flue.

Prior to the first run I dressed all the welds with an angle grinder.

Testing, Testing.....

Now for the acid test. A small amount of paper was lit and dropped down the fuel feed tube, rapidly followed by the addition of small pieces of wood. Initially,

the flame exited out of the open end of the feed tube, a quick fanning action with a piece of card above the feed tube produced sufficient draft to drive the flames DOWN and into the burn tube. This immediately started the 'rocket' action, the hot gases passing up the flue furnished the strong draft into the burn tube to produce the hot flame and roaring sound of a functioning rocket stove. Satisfied with the successful first burn the real test began.....time for coffee.

At the time of enjoying our first coffee, Sue noticed that the stove, with the fresh fuel sticking out of the feed tube, had a marked resemblance to a rooster or cockerel and by welding two shaped pieces of the window bar to the flue for the beak and the addition of two spots of weld on the sides of the flue to represent the eyes, the 'Rooster Rocket' came into being.

The stove has now been used regularly over the last month and from cold, boiling water enough for two mugs of coffee is obtained in about 8 minutes. The great thing is we are burning thin twigs and rose prunings which we would find difficult to feed into our cooker or our Godin stove. The fuel feeds in without assistance and definitely produces a clean combustion providing it is bone dry. The great thing with this size stove is that it is portable enough to store in a corner of the greenhouse and can be brought out for use in seconds.......and now here's the film

Until next time and from a sunny day in Normandie,

Cheers, Andy

© Andy Colley 2020

RELATED ARTICLES

How to Make a Simple Fuelless Cooker or Hay-box

Here's a quick and easy way to use less fuel, less water and still have a tasty and nutritious meal from a cardboard box...read more

How to Make a Wooden Fuelless Cooker or Hay-box

How to Make a Wooden Fuelless Cooker or Hay-box

A more robust model which you can keep to hand in the kitchen or to take

in a car to provide hot, nourishing food on a journey...read more

Choosing and Using Woodburning Cookers

Choosing and Using Woodburning Cookers

When we first arrived here the Spartan heating was a massive granite fireplace, the chimney of which, 1.70m by 0.70m was...read more

Heat Pumps - Case Study. Lake & River Water

Heat Pumps - Case Study. Lake & River Water

Anne-Marie and Jean-Louis have always used heat pumps as their principal source of energy...read more

Wood Chip Boiler Biomass Heater - Case Study. Organic Dairy Farm

Wood Chip Boiler Biomass Heater - Case Study. Organic Dairy Farm

A project that actually lies at the heart of what future energy conversion may be all about...read more

Home-made low-cost stove night storage heater from strawcrete and stone

Home-made low-cost stove night storage heater from strawcrete and stone

For some time we have been toying with the idea of changing the heating system in our sitting room

...read more

Home-made strawcrete and stone storage heater Part 2 - building the wall

Home-made strawcrete and stone storage heater Part 2 - building the wall

Discussing our previous experience with storage heaters and why we

wanted to make our own with ecological materials. And with the

strawcrete pad now dry, the stone work begins...read more

Home-made strawcrete and stone storage heater Part 3 - building the wall cont..

Building the wall and firing up!...read more

How to Sweep the Chimney - Tips and Strategies

When wood or coal is burned in a fire, smoke is given off, in this are particles of unburned material, tars and water, which are slightly sticky and will adhere to...read moreBetter Heat Distribution from Wood Heat 'How To'

For most of the year, the heat output from the cooker is adequate to

keep the kitchen 'comfortable'..read more